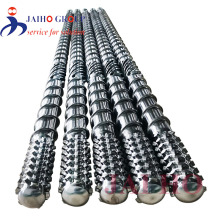

Hollow Ball Spline Shaft/Ball Spline

Basic Info

Model No.: HY-GZHJ2

Product Description

Model NO.: HY-GZHJ2 Technics: Rolling or Grounding Material: Gcr15 The Nut Material: Carbon Steel Vibration: V1 V2 V3 Accuracy Grade Code: C0, C1, C2, C3, C5, C7, C10 Torque Capacity: 74.5 Application: CNC machine etc. Specification: standard HS Code: 8477900000 Standard: DIN, JIS, ISO Feature: Recycle, Degradable, Disposable Noise: Z1 Z2 Z3 Nominal Diameter: 15mm~150mm Axial Clearance and Preloard Code: P0, P1, P2, P3, P4 Structure: Spline Product Type: Linear Motion Bearing Trademark: COWELL Origin: China HOLLOW Ball Spline Shaft/BALL SPLINE

KEYWORDS: ball spline,stainless steel ball spline,rolled ball spline,hollow ball spline shaft

BRAND:COWELL

DELIVERY TIME:10-25 DAYS

MEANS OF TRANSPPORT:BY SEA,BY AIR OR BY EXPRESS

STANDARD:ISO, DIN

DIMENSION:CUSTOM MADE

PRODUCTION INFORMATION OF BALL SPLINE

Ball splines (Ball Spline bearings) are a special type of linear motion bearing that are used to provide nearly frictionless linear motion while allowing the member to transmit torque simultaneously. There are grooves ground along the length of the shaft (thus forming splines) for the recirculating ground balls to run inside. The outer shell that houses the balls is called a nut rather than a bushing, but is not a nut in the traditional sense-it is not free to rotate about the shaft, but is free to travel up and down the shaft.

By increasing the contact area of the ball bearings on the shaft to approximately 45 degrees, the side load and direct load carrying capabilities are greatly increased. Each nut can be individually preloaded at the factory to decrease the available radial play to ensure rigidity. This process not only increases the contact area, increasing direct loading capabilities, but it also restricts any radial movement, increasing the overhung moment capabilities. This creates a sturdier structure that can handle a very strenuous working environment.

SPECIFICATION OF BALL SPLINE

ADVANTAGES OF BALL SPLINE

1.High torque

2.Low frication and noise.

3.Smooth movement.

4.Short delivery.

5.High efficiency of transferring.

APPLICATION OF BALL SPLINE

1. Engraving machines;

2. High speed CNC machinery;

3. Semi-Conductor equipment;

4. Auto-machinery.

Rolled ball screws can not only be used in general machinery, but also in many advanced industries. Rolled Ball Screw with a motor assembles electrical-mechanical actuator, which is more eco-friendly than hydraulic pump system. Nowadays it's applied to electric vehicles, solar power plants, railway decices, and many emedical and leisureequipments.

PACKAGE AND DELIVERY

1. Inner Packing is the PE film bag

2. Out packing is Paper carton or wooden box packing

3.Depend on the customer's requirements.

Delivery Detail: 20-25 working days.

OUR SERVICE

1. Measure dimension of screw and barrel

2. Complete manufacturing drawing

3. Make optimal solution based on customer's require

4.Calculate the cost of goods

5.Take photos of finished screw barrel

6 Make booking and shipping schedule

7.Send customs clearance documents

8.Arrange factory visiting schedule

9.Assistant with customers to deal other matters

COMPANY INTRODUCTION

NINGBO COWELL INDUSTRY CO.,LTD was established in 2006. It's highly involved in manufacturing of Injection Screw Barrel, Extruder Screw Barrel, rubber machine screw barrel as well as ball screw, linear guide, which are the critical component of precision machinery and mainly applied to Plastics Injection Machine, Plastic processing extruder, Machine Tool, Engineering machine, Precision Orientation Equipment and other equipments and machines.

It has professional technician team, engaged in manufacturing and researching of screw barrel. Recent years, Cowell industry places great emphasis in upgrading not only the manufacturing and quality of screw barrel but also after sales service. We uphold the concept "customer first", to provide professional, promptly and attentive service as well as better solution to continuously create value for customers.Good reputation has won the recognition from domestic and oversea market. Now we have exported to more than more than 30 countries and regions, including Middle East, Southeast Asia, France, Denmark, Finland, Italy, Poland, Brazil and Chile etc.

We warmly welcome customers oversea to build long term cooperation relationship with us!

Contact us if you need more details on Ball Spline. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ball Spline Shaft、Hollow Ball Spline Shaft. If these products fail to match your need, please contact us and we would like to provide relevant information.

KEYWORDS: ball spline,stainless steel ball spline,rolled ball spline,hollow ball spline shaft

BRAND:COWELL

DELIVERY TIME:10-25 DAYS

MEANS OF TRANSPPORT:BY SEA,BY AIR OR BY EXPRESS

STANDARD:ISO, DIN

DIMENSION:CUSTOM MADE

| Noise | Z1 Z2 Z3 |

| The Nut material | Carbon Steel |

| Nominal diameter | 15mm~150mm |

| Vibration | V1 V2 V3 |

| Axial clearance and preloard code | P0, P1, P2, P3, P4 |

| Accuracy grade code | C0, C1, C2, C3, C5, C7, C10 |

| Material | Stainless steel/GCr15 |

| Torque Capacity | 74.5 |

| Structure | Spline |

| Product type | Linear motion bearing |

PRODUCTION INFORMATION OF BALL SPLINE

Ball splines (Ball Spline bearings) are a special type of linear motion bearing that are used to provide nearly frictionless linear motion while allowing the member to transmit torque simultaneously. There are grooves ground along the length of the shaft (thus forming splines) for the recirculating ground balls to run inside. The outer shell that houses the balls is called a nut rather than a bushing, but is not a nut in the traditional sense-it is not free to rotate about the shaft, but is free to travel up and down the shaft.

By increasing the contact area of the ball bearings on the shaft to approximately 45 degrees, the side load and direct load carrying capabilities are greatly increased. Each nut can be individually preloaded at the factory to decrease the available radial play to ensure rigidity. This process not only increases the contact area, increasing direct loading capabilities, but it also restricts any radial movement, increasing the overhung moment capabilities. This creates a sturdier structure that can handle a very strenuous working environment.

SPECIFICATION OF BALL SPLINE

| Model No. | Spline nut dimensions | Flange diameter | |||

| Outer diameter | length | ||||

| D(mm) | Tolerance | L(mm) | Tolerance | D1(mm) | |

| LBF 15 | 23 | 0 | 40 | 0 | 43 |

| -0.013 | -0.2 | ||||

| LBF 20 | 30 | 0 | 50 | 0 | 49 |

| -0.016 | -0.2 | ||||

| LBF 25 | 37 | 0 | 60 | 0 | 60 |

| -0.016 | -0.3 | ||||

| LBF 30 | 45 | 0 | 70 | 0 | 70 |

| -0.016 | -0.3 | ||||

| LBF 40 | 57 | 0 | 90 | 0 | 90 |

| -0.019 | -0.3 | ||||

| LBF 50 | 70 | 0 | 100 | 0 | 108 |

| -0.019 | -0.3 | ||||

ADVANTAGES OF BALL SPLINE

1.High torque

2.Low frication and noise.

3.Smooth movement.

4.Short delivery.

5.High efficiency of transferring.

APPLICATION OF BALL SPLINE

1. Engraving machines;

2. High speed CNC machinery;

3. Semi-Conductor equipment;

4. Auto-machinery.

Rolled ball screws can not only be used in general machinery, but also in many advanced industries. Rolled Ball Screw with a motor assembles electrical-mechanical actuator, which is more eco-friendly than hydraulic pump system. Nowadays it's applied to electric vehicles, solar power plants, railway decices, and many emedical and leisureequipments.

PACKAGE AND DELIVERY

1. Inner Packing is the PE film bag

2. Out packing is Paper carton or wooden box packing

3.Depend on the customer's requirements.

Delivery Detail: 20-25 working days.

OUR SERVICE

1. Measure dimension of screw and barrel

2. Complete manufacturing drawing

3. Make optimal solution based on customer's require

4.Calculate the cost of goods

5.Take photos of finished screw barrel

6 Make booking and shipping schedule

7.Send customs clearance documents

8.Arrange factory visiting schedule

9.Assistant with customers to deal other matters

COMPANY INTRODUCTION

NINGBO COWELL INDUSTRY CO.,LTD was established in 2006. It's highly involved in manufacturing of Injection Screw Barrel, Extruder Screw Barrel, rubber machine screw barrel as well as ball screw, linear guide, which are the critical component of precision machinery and mainly applied to Plastics Injection Machine, Plastic processing extruder, Machine Tool, Engineering machine, Precision Orientation Equipment and other equipments and machines.

It has professional technician team, engaged in manufacturing and researching of screw barrel. Recent years, Cowell industry places great emphasis in upgrading not only the manufacturing and quality of screw barrel but also after sales service. We uphold the concept "customer first", to provide professional, promptly and attentive service as well as better solution to continuously create value for customers.Good reputation has won the recognition from domestic and oversea market. Now we have exported to more than more than 30 countries and regions, including Middle East, Southeast Asia, France, Denmark, Finland, Italy, Poland, Brazil and Chile etc.

| Year Company Established: | 2006 |

| Annual Sales Amount: | US$10 - 50 Million |

| Total No. of Staff: | 51 - 100 People |

| Business Type: | Manufacturer |

| Quality Certificate: | CE, ISO9001 |

| Main Export Markets: | Western Europe, Eastern Europe, South America, |

| Southeast Asia, Mid East, Africa |

Contact us if you need more details on Ball Spline. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Ball Spline Shaft、Hollow Ball Spline Shaft. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Ball Screw And Nuts

Premium Related Products

Other Products

Hot Products

Universal Plastic Film Sealing Cutting Blade / KnifeMost Popular Stamping Dies for Plastic ProcessingFactory Supply Variable Frequency DriveTwin Parallel Screw Barrel (Weber, DS etc.)The Silicone Machine Screw BarrelDouble Coloured Injection Molding Machine Barrel18mm Vertical Injection Molding Machine Barrel40mm Screw Barrel for Bakelite MachineToshiba Nozzle for Injection Molding BarrelToshiba Injection Screw Torpedo HeadTorpedo Head for ScrewParallel and Concial Screw for Extruder MachineSingle Extruder Screw for Extruder MachineInjection Molding Machine Barrel (EPB400)Injection Screw EPS4000 (Nitriding screw)Toshiba Injection Molding Machine Screw Barrel