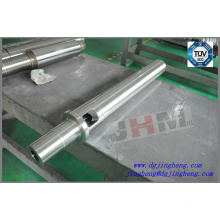

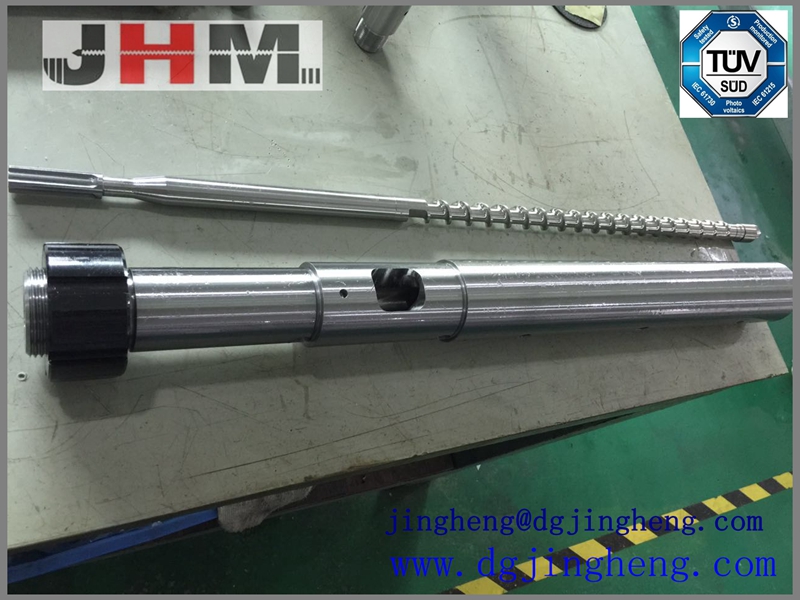

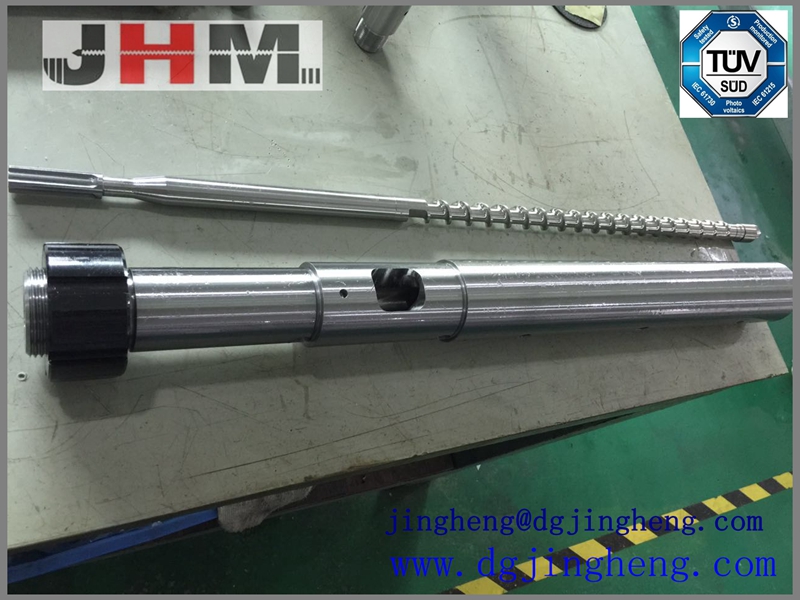

Niigata D22 Screw Barrel for Injection Molding Machine

Basic Info

Model No.: Niigata machine

Product Description

Model NO.: Niigata machine Technics: Push Material: Bimetallic Alloy L/D: 15 to 55 Linearity of Screw: 0.015mm Surface Roughness: Ra 0.4 Nitration Fragility: ≤grade 1 Bimetallic Hardness: HRC56 to 65 Origin: Dongguan, Guangdong Standard: GB Feature: Recycle Screw Diameter: 20millimeter-220millimeter Nitrided Hardness: HRC 55-65 Nitriding Layer Depth: 0.5-0.8mm Thickness of Cr-Coating Layer: 0.03-0.1mm Depth of Bimetallic Layer: 2mm to 5mm Trademark: JHM HS Code: 84779000

The most compact body in the industry

The most compact body in the industry

NIIGATA has a distinctive injection unit structure to minimize machine installation area. We can proudly introduce our product to the customer who can not spare enough space for large machines. Now, you can utilize your space to the fullest! What's more, the height of our machine is lower than out conventional model and the operability is improved. Super wide platen for easy mold installation

This new model is equipped with 50mm wide mold space than a conventional model. Now it can accommodate even larger molds. In addition, platen rigidity is much increased thanks to CAE analysis. During clamping, this change helps to minimize the deformation of mold. And by adopting linear guide system, mold open/close movement is flawless. Eco-friendly sealed Ball Screw

Sealed ball screw is applied to injection axis and clamping axis to prevent grease scattering. Grease consumption rate is drastically reduced, and a waste-grease recovery port is equipped at clamping side. Screw Production Process

Customer Order--- Material Procurement---Normalizing/Homegenizing---Dring---Rough Turing---Rough Thread Rooling---Alignment and Stress Release---Fine Rough Rolling---Mixing/Stirring Zone---Alignment Polishing---Grinding---QC---Iron Nitrogenizing(120 hour)---Alignment/Polishing---Polishing/Grinding---Cryogenic treatment---PVD plating---O.D Grinding---FQC---Packing and Shipping

Our Advantages

1. Over 20 years experiences of manufacturing and designing screw

2. Professional design and R&D team

3. Customized service for each customer

4. Fast response to each inquiry

5. In-time after sale service

FAQ:

1. What's the quality of JHM screw barrel like?

We apply advanced manufacturing management system, including professional design and order processing software and ERP system, to assure product quality and competitive cost.

2. How long does it take to receive my product after I place the order ?

Delivery time varies from 25 to 35 days according to the different materials of screws.

3. How about the after service of JHM product?

Generally, customer often demands the QC to check our goods when we are going to ship. In case of the customer receives shipment and finds some quality problem, we will accept a claim if it is our responsibility.

Want to know more? Welcome to view our official website: Contact us if you need more details on Screw. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Screw Barrel、Injection Screw. If these products fail to match your need, please contact us and we would like to provide relevant information.

The most compact body in the industry

The most compact body in the industryNIIGATA has a distinctive injection unit structure to minimize machine installation area. We can proudly introduce our product to the customer who can not spare enough space for large machines. Now, you can utilize your space to the fullest! What's more, the height of our machine is lower than out conventional model and the operability is improved. Super wide platen for easy mold installation

This new model is equipped with 50mm wide mold space than a conventional model. Now it can accommodate even larger molds. In addition, platen rigidity is much increased thanks to CAE analysis. During clamping, this change helps to minimize the deformation of mold. And by adopting linear guide system, mold open/close movement is flawless. Eco-friendly sealed Ball Screw

Sealed ball screw is applied to injection axis and clamping axis to prevent grease scattering. Grease consumption rate is drastically reduced, and a waste-grease recovery port is equipped at clamping side. Screw Production Process

Customer Order--- Material Procurement---Normalizing/Homegenizing---Dring---Rough Turing---Rough Thread Rooling---Alignment and Stress Release---Fine Rough Rolling---Mixing/Stirring Zone---Alignment Polishing---Grinding---QC---Iron Nitrogenizing(120 hour)---Alignment/Polishing---Polishing/Grinding---Cryogenic treatment---PVD plating---O.D Grinding---FQC---Packing and Shipping

Our Advantages

1. Over 20 years experiences of manufacturing and designing screw

2. Professional design and R&D team

3. Customized service for each customer

4. Fast response to each inquiry

5. In-time after sale service

FAQ:

1. What's the quality of JHM screw barrel like?

We apply advanced manufacturing management system, including professional design and order processing software and ERP system, to assure product quality and competitive cost.

2. How long does it take to receive my product after I place the order ?

Delivery time varies from 25 to 35 days according to the different materials of screws.

3. How about the after service of JHM product?

Generally, customer often demands the QC to check our goods when we are going to ship. In case of the customer receives shipment and finds some quality problem, we will accept a claim if it is our responsibility.

Want to know more? Welcome to view our official website: Contact us if you need more details on Screw. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Screw Barrel、Injection Screw. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Barrel Series

Other Products

Hot Products

Universal Plastic Film Sealing Cutting Blade / KnifeMost Popular Stamping Dies for Plastic ProcessingFactory Supply Variable Frequency DriveTwin Parallel Screw Barrel (Weber, DS etc.)The Silicone Machine Screw BarrelDouble Coloured Injection Molding Machine Barrel18mm Vertical Injection Molding Machine Barrel40mm Screw Barrel for Bakelite MachineToshiba Nozzle for Injection Molding BarrelToshiba Injection Screw Torpedo HeadTorpedo Head for ScrewParallel and Concial Screw for Extruder MachineSingle Extruder Screw for Extruder MachineInjection Molding Machine Barrel (EPB400)Injection Screw EPS4000 (Nitriding screw)Toshiba Injection Molding Machine Screw Barrel