PP PE plastic wet film squeezing machine

Product Description

WHY CHOOSE US?!

1.JAIHO only supply competitive advantage products.

2.Full refund or Free replacement incase of bad quality or late delivery!

3.JAIHO are focus on service for solution, not only supply screw barrel parts.

4.Quality is our culture, with us your money in safe your business in safe!!!

5.JAIHO is the 2018 year the most welcomed Alibaba gold supplier!!!

Please you can check our factory video from Facebook or Youtube as below link(100% original):

Facebook: www.facebook.com/jaihogroup.com.cn

Youtube: https://youtu.be/jFI8SeAqZBE

Why you need it? ---- Dirty PE PP film

This squeezing dewatering machine for waste plastic recycle.Especially the agricultural film, they are dirty and often with clay, sand, grassroots, nails, wire, etc. So before granulation we have to clean and wash them.

Why you need it? ----Wet PE PP film

After clean and wash the dirty waste film, we have to squeeze the film. This squeezing dewatering machine for waste plastic recycle washing line is not only with high capacity but also with low energy consumption. The final moisture content can up to 3%. It will help you reduce the cost and improve productivity.

What advantage of it ?

It makes materials easier to be granulated and dry, and if you use it, you will do not need following three machines: dewatering machine, pipe drying system and agglomerator, only need one stage extruder recycling machine instead of two or three stage recycling machines.

What to do?

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

How to choose it ?

Film squeezing machine

Features:

1,Gearbox : ZLYJ315 (Guomao hardened gears)

2,Screw Diameter:φ300mm

3,Screw Length: 1300

5,Inverter Power: 90KW (DELTA)

4,Mainly Motor power:90KW 5,Inverter Power: 90KW (DELTA)

6,Screw and Barrel adopt 38CrMoAlA and nitriding treatment

7,Barrel heating power: 1zone*6KW=6KW, heating by electric

8,Capacity: 400~600kg/h.

9,Pelletizer(Cutting with 4 knifves) with Inverter : 2.2KW

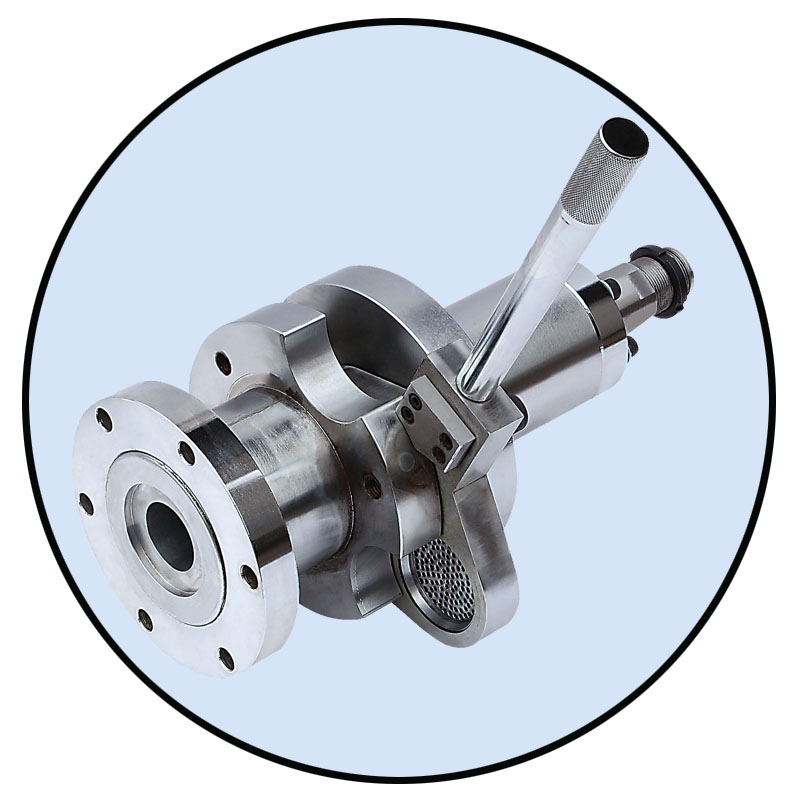

10. diehead: Discharging hole diameter:12mm, copper pipe cooling

11, Air blower:3.0KW with transport pipe and stainless Storage Hopper: 300L capacity

12,Conveyor with inverter

13,Three-phase power: 380V/50HZ 14.water content <3%

100% Inspection for each screw barrel according to drawing.

100% Qualified for each screw barrel before delivery.

100% One year guarantee with inspection report & raw material MTC to customer.

1.Customer:What is this line guarantee time?

1 year since B/L date

2. Customer:When is this machine can be delivery?

Normally:30 days when get deposit

3. Customer:How many containers need that for loading this complete production line?

If you don't need auxiliary machine like mixing unit,milling machine,crusher...One 40HQ container is enough.If need these auxiliary machine,you should also need one 20GP container more.

4. Customer:If we want to change some part of the complete line,for example we want to change the motor brand,frequency converter brand,if it is ok for you?

Yes,it is no problem,we can change to the brand what you need if it is necessary for you,the price is also can be changed.

Product Categories : recycling machine

Premium Related Products