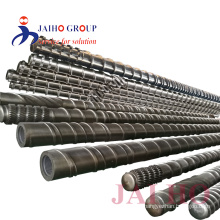

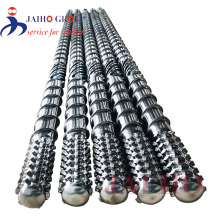

Extruder Single Screw Barrel/ Screw Barrel for PP Film Pelletizing Machine

Product Description

WHY CHOOSE US?

1.JAIHO only supply competitive advantage products!

2.Full refund or Free replacement in case of bad quality or late delivery!

3.JAIHO are focus on service for solution, not only supply screw barrel parts!

4.Quality is our culture, with us your money in safe your business in safe!!!

5.JAIHO is the 2018 year the most welcomed Alibaba gold supplier!!!

Please you can check our factory video from Facebook or Youtube as below link(100% original):

Facebook: www.facebook.com/jaihogroup.com.cn

Youtube: https://youtu.be/jFI8SeAqZBE

We are not only sale recycling screw barrel only, also we can supply the right good recycling machine spare parts to you with competitive price, we can do ONE-STOP service for you to save your time and save your money.

Detail Showing for the plastic recycling screw barrel

Vented/Gas/Degassing Port Design

Bimetallic Recycling Pelletizing Screw Barrel

As the granulator is mostly use recycled material, the material contains a lot of impurities and corrosive ingredients, so according to customer demand we will recommend to use bimetallic screw and Bimetallic Barrel to improve the screw barrel more longer lifetime.

High Speed feeding barrel-separately water jacket

This separate water cooling jacket design do have excellent cooling performance and higher output capacity, with longer and deeper rectangle grooves design with internal complex cooling cycling system.

Big Feeding Mouth

We have big feeding mouth design to improve the feeding speed to increase the output capacity, especially for the LDPE/HDPE, PP film raw material recycling.

when customer has agglomerator, it's easy for feeding and faster than the normal feeder.

also inside of the feeder have slant slot

Straight/ Spiral Grooved/Eccentricity Feeding Design

We make different feeding groove shape like straight groove, diagonal groove and eccentricity to improve feeding speed, with our high-speed screw, it will highly increase extruder output.

Our various type of recycling pelletizing screw barrel:

For over one decades Jaiho has been a leading supplier in machine components for the Plastic, Food and Rubber industry. Flite Technology has earned the reputation as an innovator and industry leader in the manufacturing of precision single and twin feed screws and barrels. Whether it's new, rebuilding, designing or repair, you can be confident our service, quality and performance will be unsurpassed.

We also offer very aggressive competitive pricing. Pick up and delivery service is available as well as reverse engineering for existing worn out parts.

We are focus on service for solution, not only supply screw barrel.

You can find our Jaiho factory videos with detail workshop and products photos in below link:

Facebook: www.facebook.com/jaihogroup.com.cn

Factory Video: https://youtu.be/jFI8SeAqZBE

Our new workshop 12000SQM, Totally have 5 engineers team, and 50 good experinced employee, registered capital 8 billion USD. we are also have German technical cooperation with 20% share.

We are foucs on each process to make sure each set screw barrel is qualified according to Germany technical requirement.

We will check each parameters for finished screw barrel to make sure all qualified according to customer specifications and drawings.

*100% Inspection for each screw barrel according to drawing.

*100% Qualified for each screw barrel before delivery.

*100% One year guarantee with inspection report & raw material MTC to customer

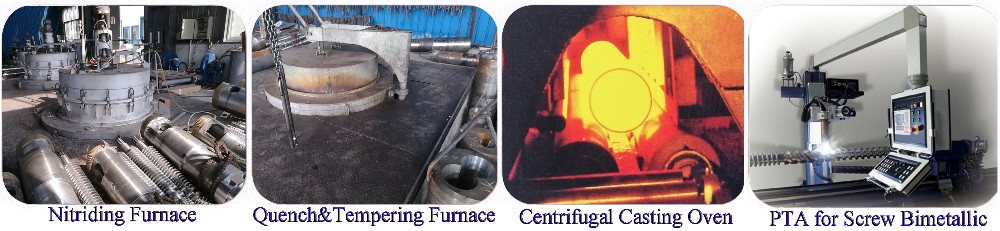

We have own heat treatment furnace and nitriding furnace to make customer hardness requirement, also we do the bimetallic/allloy screw barrel by PTA spraying and centrifugal casting process.

We have Professional engineer team to do Oversea Service for Technical Support and Measuring.

1. Q: How about JAIHO?

R:10 years experienced, Germany Technical invested since 2002, leading screw barrel manufacturer in China.

2. Q:What's Jaiho capacity?

R:Passed ISO 9001:2008, Our workshop 12000SQM, 5 Engineer team, 50 good experienced employee, All CNC

computer control screw processing, 1000sets screw barrel capacity per month.

3. Q:What's the delivery time of HDPE LDPE FILM RECYCLING PELLETIZING SCREW BARREL?

R:for regular size, we have finished stock and semi-finished stock, 2weeks max enough

for customized, normally 3~4weeks.

4.Q:How about Jaiho screw barrel quality and price?

R:Germany Technical invested, Good quality in China with competitive price and globle after-sale service

5. Q:How to make sure the screw suitable for my extruder?

R:Let's know what size you want and we can check it with our drawing.We have lots of BEX,KMD,CMT,AMUT,

Weber,Haitian,ChenHsong,ChenDe,Tedric,JSW, ect. If your extruder is made in China,it's easy to get the original

drawing.Any way,Our engineer can measure in your factory, his English is good,so cost is saved.

6. Q:what's the life time and guarantee buy from Jaiho screw barrel?

R:3~5years life time for nitriding ones and bimetallic ones will be longer

One year min. Guarantee

7.Q:Where is Jaiho factory and how to reach there?

R:At Dinghai, Zhoushan City,Zhejiang Province. It's near Shanghai City and Ningbo City,If you want to

visit us,we can pick up you there.

8.Q:How to contact with you?

R:just reply to me below if have any question.

Product Categories : Single Screw Barrel > Single Screw Barrel

Premium Related Products